Sinoguide Technology R&D technical manager Mr.William is developing high performance thermal interface materials (TIMs) that have a superior ability to transfer heat and a strong capacity to keep cool.

SHENZHEN, China - Dec. 22, 2016 -- For the microelectronics field, the military and private sectors alike need solutions to technologic challenges. Sinoguide Technology R&D technical manager Mr.William is developing high performance thermal interface materials (TIMs) that have a superior ability to transfer heat and a strong capacity to keep cool.

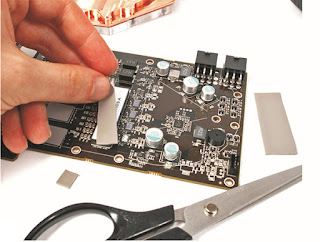

Thermal interface materials have long been recognized as the market's most effective thermal management products to fill unique and intricate air voids and gaps. Now, these trusted materials take device protection one step further by integrating electromagnetic energy absorption functionality. With thermal conductivity of 1.1 W/m-K and satisfied EMI absorption, TCP110U provides robust thermal management control and an added level of EMI protection.

TCP110U improved wet-out at the interface results in thermal performance that is superior to other competitive materials with a similar grade. Thermal conductivity is also enhanced by the material's natural tack on one side, which eliminates the requirement for any thermally-impeding adhesive layers and also makes component rework simple. With another side fiberglass reinforced, it is highly improved on puncture, shear and tear resistance.

Our global team of Applications Engineers are knowledgeable about silicone and applications spanning multiple industries. These include metallurgical casting, electronics, chemical, nuclear, defense/aerospace, solar, LED, semiconductor, and other high temperature processes.

Regardless of your product design phase (concept, prototyping, or mass production), we offer technical answers to some of your most challenging problems with a fast response time.